Wedding rites are changing

Jolanta Paðkevièienë

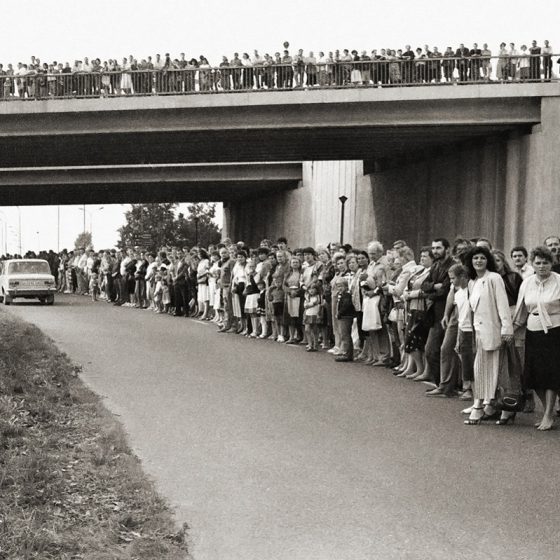

These days, when peoples and their customs are all mixing, weddings that are celebrated in accordance with centuries-old traditions can probably only be found in some mountain village, or in an Eskimo community cut off from the world by ice, or seen in films about folk traditions.

Even Lithuanians, who are not enthusiastic about taking on new things, and who are proud of their customs that have lasted since pagan times, no longer have traditional weddings.

They often laugh that the only events they celebrate joyfully are weddings. Maybe that is why the occasion, which is celebrated with relatives and close friends, often adopts customs from other parts of the world.

Traditions Are Barely Alive

Over the last decade, not only premarital life but …